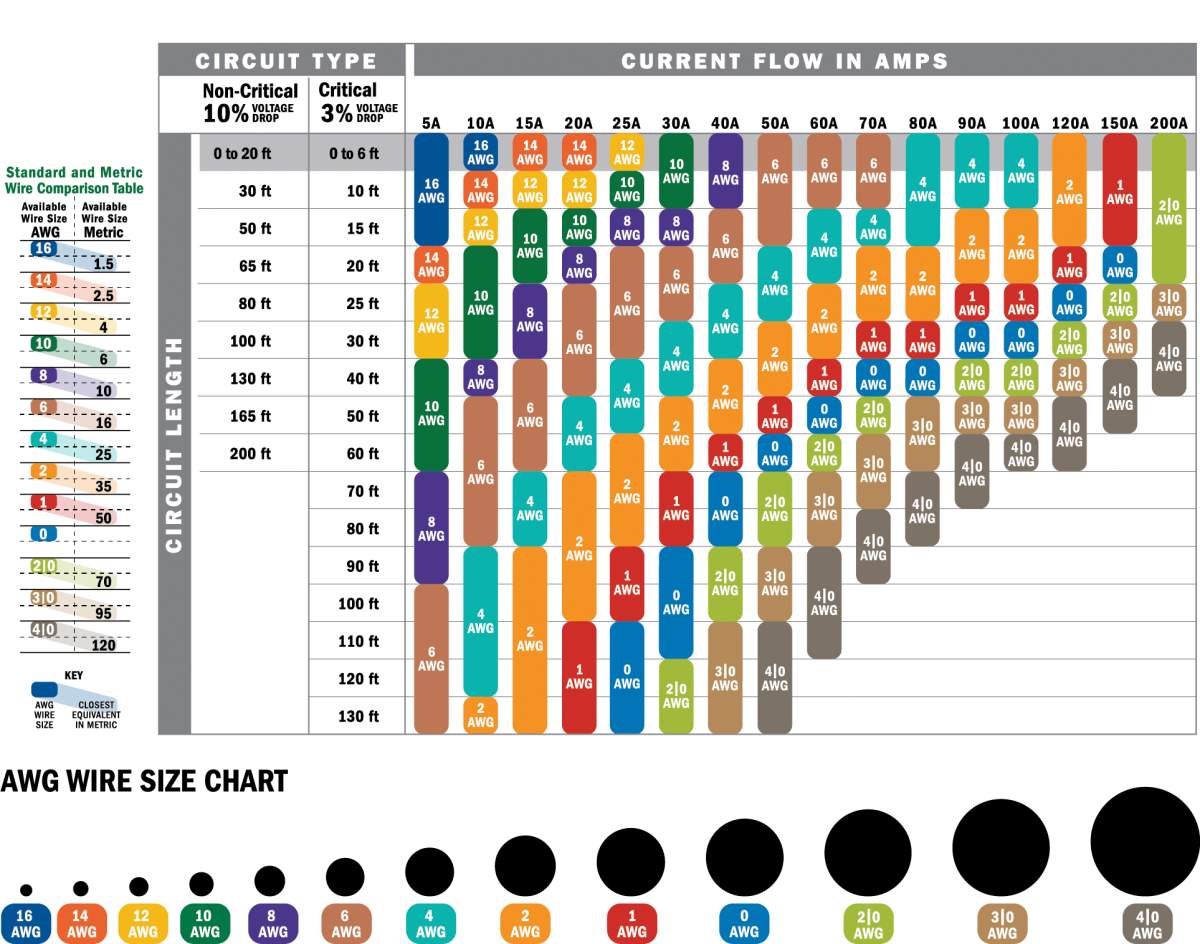

If your circuit needs 100 amps of current, the battery cable will absorb 24 watts of power because of it’s resistance. At the source, or battery, you will read 12 volts using a voltage meter, but at the other end of the cable your voltmeter will only read 11.76 volts (12 volts -2%). Why is voltage drop important? for example, let’s say that your length of battery cable is connected to a 12 volt source and has a voltage drop of 2%, which is considered adequate for almost all electrical systems. This voltage drop is influenced by the diameter of the copper conductors inside the cable, and the total length of the cable – The longer the battery cable is, the higher the voltage drop will be, and the larger the diameter, or gauge (AWG) of the battery cable, the less the voltage drop will be. Voltage drop is simply the voltage seen at one end of the cable minus the voltage seen at the other end of the cable. As electricity flows through a cable, there is an inherent resistance to the flow of that electricity which will generate heat in your battery cable and manifest itself in the form of what is called a voltage drop. When choosing the size of a battery cable to power your electrical system or project, it is important that it is sized appropriately. It is always a good idea to cover the terminated ends of your automotive wire with some heat shrink tubing. Basically, if you crimp your wire and terminal together, and you cannot pull them apart, the connection will most likely suffice. The key is to make sure that there is good electrical contact between the copper strands of the wire, and the barrel of the terminal or connector. However, in 95% and more cases, a good crimp will work just as well. Is it better to solder or to crimp connectors to automotive wire? Soldering is superior since it creates a maximum amount of surface contact between the wire and the terminal or connector. The voltage reading on your volt meter at the end of the wire will only be 9.6 volts, and the wire is absorbing a whopping 48 watts of power! Now let’s say your wire has a 20% voltage drop. If you are running 20 amps through your wire then your wire is absorbing 4.8 watts of power. So if you put a volt meter on your battery and read 12 volts, when you put your volt meter on the end of the wire, you will read 11.76 volts. That leaves 11.76 volts, or units of work left. If you’re wire has a 2% voltage drop, then the wire is using up 0.24 volts, or units of work.

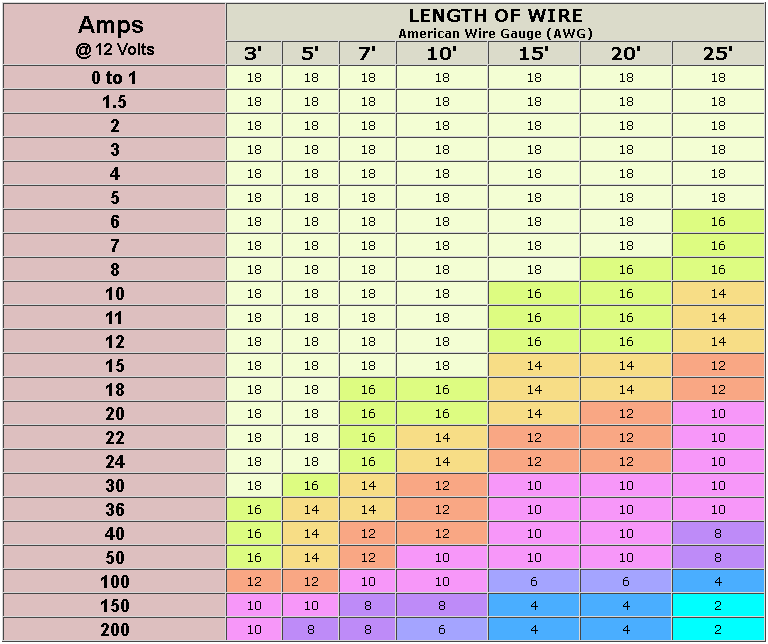

In its simplest terms, you can think of 12 Volts as during 12 units of work. This lost energy is realized in the form of a voltage drop at the end of the wire. Why is the size of an automotive wire so important? When electricity passes through a wire, The wire resists the electricity and some of it is converted into heat that is absorbed by the wire. Based on the chart above, you would want to use 12 gauge automotive wire for your floodlights. The length the wire needs to be to connect to the floodlights is 9 ft.

For example, you want to add some flood lights to your vehicle. If this AWG metric calculator doesn't provide you with the information you need, please get in touch with the technical experts of The Cable Lab who will be pleased to answer your questions or calculate the appropriate AWG/metric size for your installation.In order for your automotive electrical system to perform properly, your wire must be sized properly based on the amount of current (amperage) the wire must carry, and the length that the wire needs to be. The following AWG metric conversion table converts AWG to mm and inches, and also lists the cross sectional area (mm2). The most common method of referring to conductor sizes uses the cross-sectional area, expressed in mm². Our Tri-Rated cable, compliant with American standard UL758, can be converted to AWG cable conductor sizes if required. Our Belden cables and the pairs in instrumentation cable are some of the electrical cables where the conductor size is expressed as an AWG figure. It means the higher the AWG number is, the smaller the wire diameter is. The American Wire Gauge chart is based on the number of dies originally required to draw the copper down to the required dimensional size. AWG or American Wire Gauge is the US standard measure for the diameter of electrical conductors.

0 kommentar(er)

0 kommentar(er)